IceLoss – wind turbine icing loss assessment

Ice formation on rotor blades influences the aerodynamic properties of the blades leading potentially to large power losses in a wind farm. Production losses of 50 % or more have been observed during winter months characterized by heavy icing. Icing can thus result in large annual production losses. To our experience in working with multiple wind farm post-construction production analysis and pre-construction energy yield assessments, icing loss are the second highest source of icing losses after wake losses in Nordics.

To estimate expected icing losses for a planned wind farm, we have developed an in house state-of-the-art method IceLoss which models the expected icing losses of a wind farm based on simulations with the mesoscale weather model WRF, combined with in-house post-processing algorithms.

The results of the model include hourly and long-term estimate of the icing losses for the wind farm based on the modelled icing climate at the site. The results are presented for turbine with and without ice protection systems (blade heating, anti- and/or de-icing).

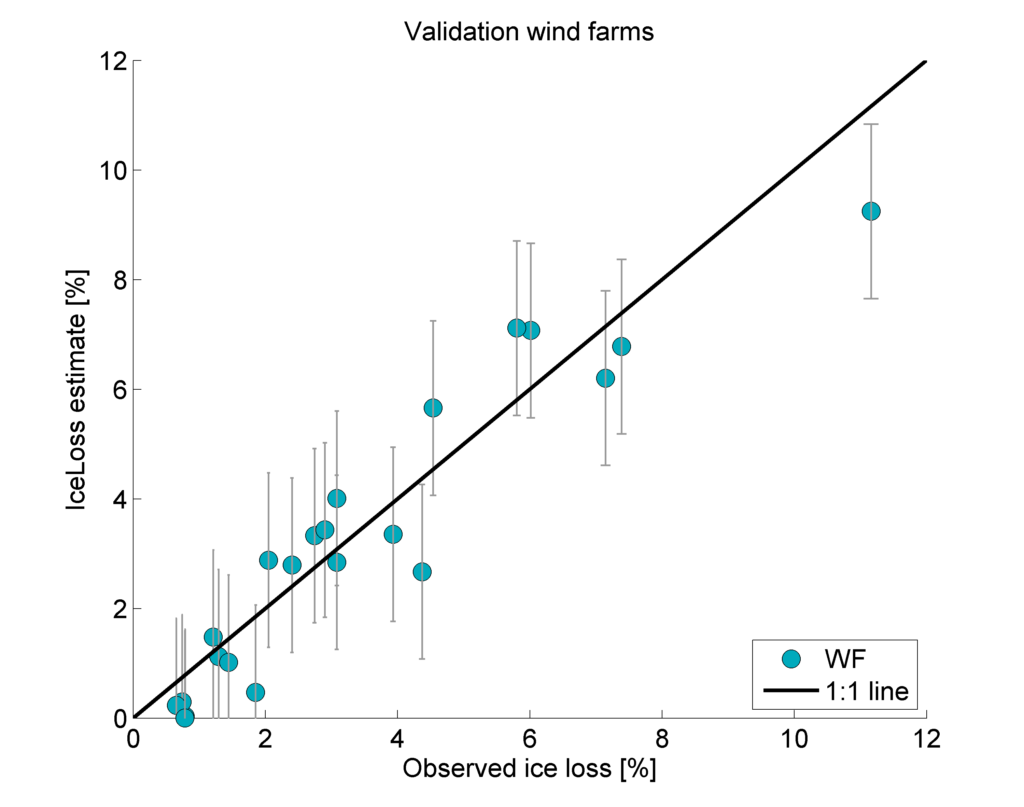

The latest IceLoss model is validated with data from 22 operational wind farms.

As references, we have produced IceLoss reports for more than 150 wind farms in cold climates.

Request Offer

Validation results of the IceLoss2 model

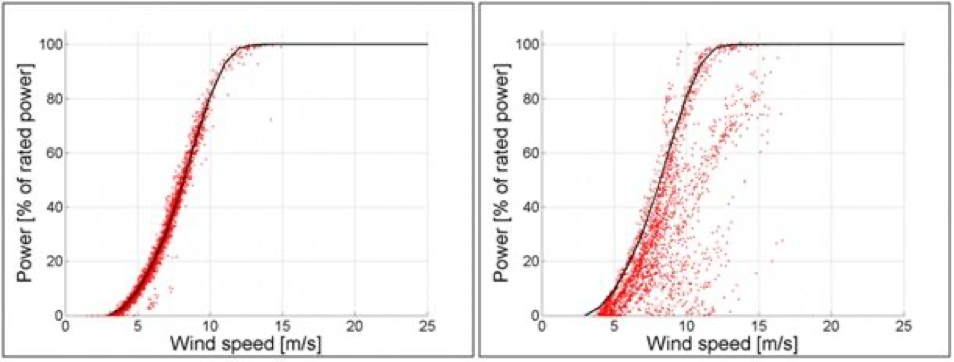

| Production Data – May | Production Data – November |